WHAT IS MICRO 12 MM?

- It can be used as primary reinforcement in concrete,

- High strength, polymer based,

- It provides crack resistance and load bearing with two different materials in its composition,

- It is a long-lasting, Synthetic Macro Fiber Reinforcement.

- Micro 12 mm is homogeneously dispersed in the concrete, providing the desired concrete appearance and strength with minimum labor and cost during and after pouring, and offers ease of application to projects.

It contains;

- Thanks to the single fiber copolymer structure it contains, it prevents load transfer and crack formation arising from internal stresses, and increases tensile strength in bending and splitting.

- In addition to the copolymer structure, shrinkage and heat-related cracks are prevented thanks to the polypropylene fibers in the mixture at a special rate.

MICRO CONCRETE 12 MM

USAGE AREAS OF MACRO SYNTHETIC FIBER REINFORCEMENT

Field and Ground Concretes

- Factory Floor Concretes and Stock Areas

- Cold Storage Floor Concretes

- Logistics Bases

- Topping Concretes

- Fuel Stations

- Metro Stations Waiting and Walking Areas

- Concrete Roads

Housing Construction

- Residential Screeds

- Open-Closed Car Park Ground Concrete and Other Traffic Areas

- Landscaping and Walkways

- Outdoor & Indoor Pool Concretes

Coastal Structures and Harbors

- Marine Port Concrete Coatings

- shipyards

- marinas

- Piers and Docks

- Coast Guard Elements

- Dalgakıran Concrete Coatings

Water Structures

- Hydroelectric Power Plants (HEPP)

- Drinking Water and Sewerage Projects

- Irrigation Projects

- Hydrology and Flood Studies

- Channel Structures

Precast Elements

- Concrete Pipes

- Concrete Blocks

- Retaining Walls

- segments

- Highway Curbs

- Liquid Tanks

- Facade Panels

mines

- Ground Stabilization Shotcrete

- Mirror – Transition and Landing Road Concretes

- Factory Floors

- Underground Rooms

- Ore Pits Filling Kits

tunnels

- Ground Stabilization Shotcrete

- Filling Shotcrete

- Tunnel Base Coating Concretes

- Invert and Full Height Concrete Coatings

- Tunnel Segment Coatings

- Stabilization of Slopes

TECHNICIAL SPECIFICATIONS

| Characteristic | Material Feature |

| Raw Material | 100% Pure Copolymer PP/PE |

| Length | 12mm |

| Tensile Stress | 550 - 750 MPa |

| Modulus of Elasticity | 5.75 GPa |

| Surface Texture | Deformed Surface |

| Fiber Count | 220.000 Pieces/kg |

| Intensity | 0.91 g/cm3 |

| Melting point | 162-168 °C |

| Combustion Point | 398 °C |

| Water Absorption | None |

| Acid / Alkali Resistance | Perfect |

| Standard | ASTMC-1116 |

DOSAGE and USE

Micro 12 mm has dosages varying between 1-10kg/m3 in different applications. In average ground conditions, under average loads of shotcrete and ground concrete, Micro 12 mm is often used in the dosage range of 2-4 kg/m3.

For a homogeneous mixture, it is sufficient to add Micro 12 mm to the concrete mixture by putting it on the aggregate band in the concrete plant.

If it is desired to be mixed at the construction site, it is recommended to add it to the transmixer at the specified dosage and mix for a minimum of 5 minutes. After this period, a homogeneous mixture is obtained and applied to the field without the need for any operation other than the standard concrete casting application.

TECHNICAL ADVANTAGES- It prevents shrinkage cracks and microcracks.

- It has high energy absorption capacity.

- It increases the fatigue resistance and ductility of concrete.

- It reduces surface wear.

- Increases impact resistance.

- It provides high bending and splitting tensile strength.

- It works in 3 dimensions, undertakes the task of pressure reinforcement against negative moments on the surface.

- It increases durability by not being corroded.

- It gives extra resistance to the concrete weakened by freezing and thawing.

- It ensures that the concrete, which decomposes in acidic and salty environments, stays together.

- Increases fire resistance.

- It provides the concrete to gain elastoplastic behavior.

- It has a high brittleness rate.

- Thanks to its fringed structure, it has a superior adherence ability than other fibers.

COST AND APPLICATION ADVANTAGES

- It provides an advantage in terms of workmanship during application.

- The loss of time during the assembly of the steel mesh is not experienced with Micro 12 mm.

- The purchasing cost is more advantageous than steel mesh and steel wire.

- Since rust is not used, the floor thickness is reduced.

- Non-corrosion extends service life and maintenance periods.

- It is not damaged during stocking and can be stored for a long time.

MICRO 12 MM PROVIDES RESISTANCE TO RESTORATION CRACKS

One of the most negative factors that reduces the strength of concrete is shrinkage. Shrinkage, which means the shrinkage of concrete, brings with it superficial or deep cracks in the concrete. Expansion or contraction, swelling, creep and shrinkage caused by thermal effects are the main events that cause early volume changes in concrete.

MICRO 12MM

- It creates resistance to shrinkage stresses.

- It minimizes the amount of cracks formed due to shrinkage.

- It is homogeneously dispersed in the concrete and adheres to the concrete very strongly.

- It confronts the crack at the first moment and prevents the crack from progressing.

TENSILE TESTS IN BENDING AND SPLITTING

ISTANBUL TECHNICAL UNIVERSITY BUILDING MATERIAL LABORATORY

Concrete prism samples of 150x150x600 mm size belonging to C30 concrete class containing micro 12 mm brand, copolymer/polypropylene carrier synthetic fiber (12 mm long) and steel wire (60 mm length, 0.75 mm diameter, hook tip) from another company were produced. In addition, 150x150x150 mm cube samples were produced to determine the split-tensile strengths. In order to compare the performance criteria of these concretes produced using copolymer/polypropylene carrier synthetic fiber and steel wire, witness samples belonging to the same concrete class were produced and bending and splitting-tensile tests were carried out. Obtained results are given below.

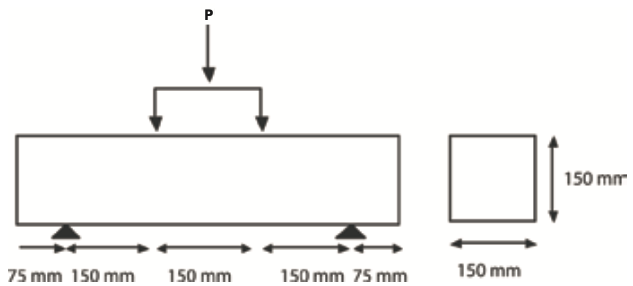

PRISM EXPERIMENTS

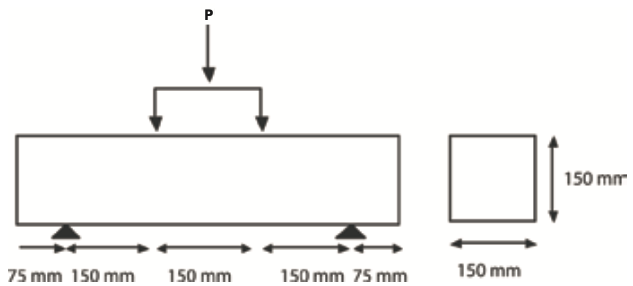

Closed-loop deformation-controlled one-third load bending tests were conducted on concrete prisms produced using compositions with constant cement content, water/cement ratio and workability (10-12 cm slump). The definition of the samples, the experimental setup and the results obtained are given below.

Test Samples

Each sample is prism-shaped, measuring 150x150x600 mm.

The experimental setup

The experimental setup of the samples placed in such a way that the distance between the supports is 450 mm is given in the figure.

Concrete Prism Experiment Setup

BENDING AND SPLIT EXPERIMENT RESULTS

Bending results and split-tensile test results on concrete prism and concrete cube specimens are given in the table below.

Average Flexural Strengths

| SAMPLE CODE | AVERAGE FLEXIBILITY STRENGTH (MPA) |

| Witness | 3.62 |

| 2kg/m3 Micro 12 mm | 3.63 |

| 4kg/m3 Micro12 mm | 3.79 |

| 6kg/m3 Micro 12mm | 4.11 |

| 20kg/m3 Steel Wire Reinforcement | 3.63 |

| 30kg/m3 Steel Wire Reinforcement | 4.06 |

Splitting - Tensile Strengths

| SAMPLE CODE | SPLIT - TENSILE STRENGTH (MPA) |

| Witness | 3.66 |

| 2kg/m3 Micro 12 mm | 3.74 |

| 4kg/m3 Micro 12 mm | 4.15 |

| 6kg/m3 Micro 12 mm | 4.46 |

| 20kg/m3 Steel Wire Reinforcement | 3.71 |

| 30kg/m3 Steel Wire Reinforcement | 4.21 |